Reducing the cross sectional area of the speci.

Fabric tensile strength test pdf.

Tensile strength testing of fabric.

Each testing method has its own advantages and drawbacks.

Here two testing were done.

Fabric in which the threads are coated with abrasive has also been effective.

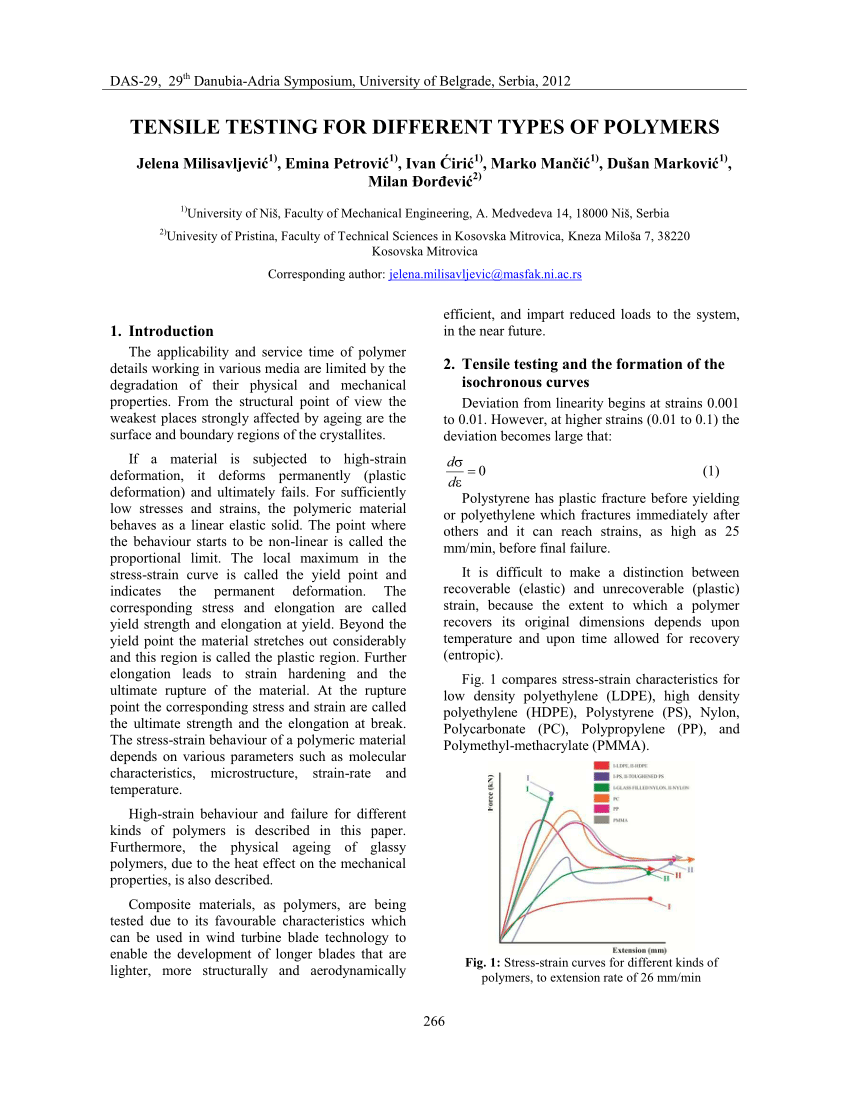

Introduction to tensile testing 5 fig.

Tensile strength of the material used.

Fabric tensile strength test methods.

Tensile testing of textile fabrics in accordance with astm d 5034 application report introduction astm d 5034 standard test method for breaking strength and elongation of textile fabrics grab test is used to determine the breaking strength and elongation of woven non woven and felted fabrics.

It is an inherent property of the fabric and so forms part of the specification for fabrics which are to be made into upholstery.

Current edition approved june 1 2008.

To get the material s tensile strength a test method is strongly required where the stress distribution over the specimen width is well known.

Specimens in the grab test are easier to prepare and the testing.

By treating the fabric as a bundle of yarns they applied.

For other fabrics however other testing temperatures must be used so that under the effect of the sunrays they don t heat up too much.

To quantify the tensile strength of a piece of fabric two testing methods are often used namely the grab test and the strip test.

Fabric strength enhancement and it will likely play an important role in reinforcing the composite.

6 the low strain region of the stress strain curve for a ductile material tic contribution and e e is the elastic contribution and still related to the stress by eq 3.

4 1 a test specimen is clamped in a tensile testing machine and a force applied to the specimen until it breaks.

Seam slippage method.

Tensile strength is one of the most important mechan ical properties for woven fabrics.

For a pvc coated polyester fabric a temperature of 70 c can be reached without any problems.

At first we take specimen 4 x6.

The two jaws are fixed on both side of the specimen from 1 edge.

Shahpurwala and schwartz16 attempted to predict the tensile strength of woven fabrics using derived strength distributions of the constituent yarns.

Seam slippage is the condition where a seam sewn in the fabric opens under load.

Values for 1 this test method is under the jurisdiction ofastm committee d13 on textiles and is the direct responsibility of subcommittee d13 60 on fabric test methods specific.

D651 test method for test for tensile strength of molded electrical insulating materials withdrawn 1989 3 d882 test method for tensile properties of thin plastic.

One hour before testing and that the clamps must also be at the sample temperature if at all possible.

Only this knowledge makes it possible to compute the tensile strength from the breaking or maximum force directly measured by the testing machine.